Backing innovation when others hesitated

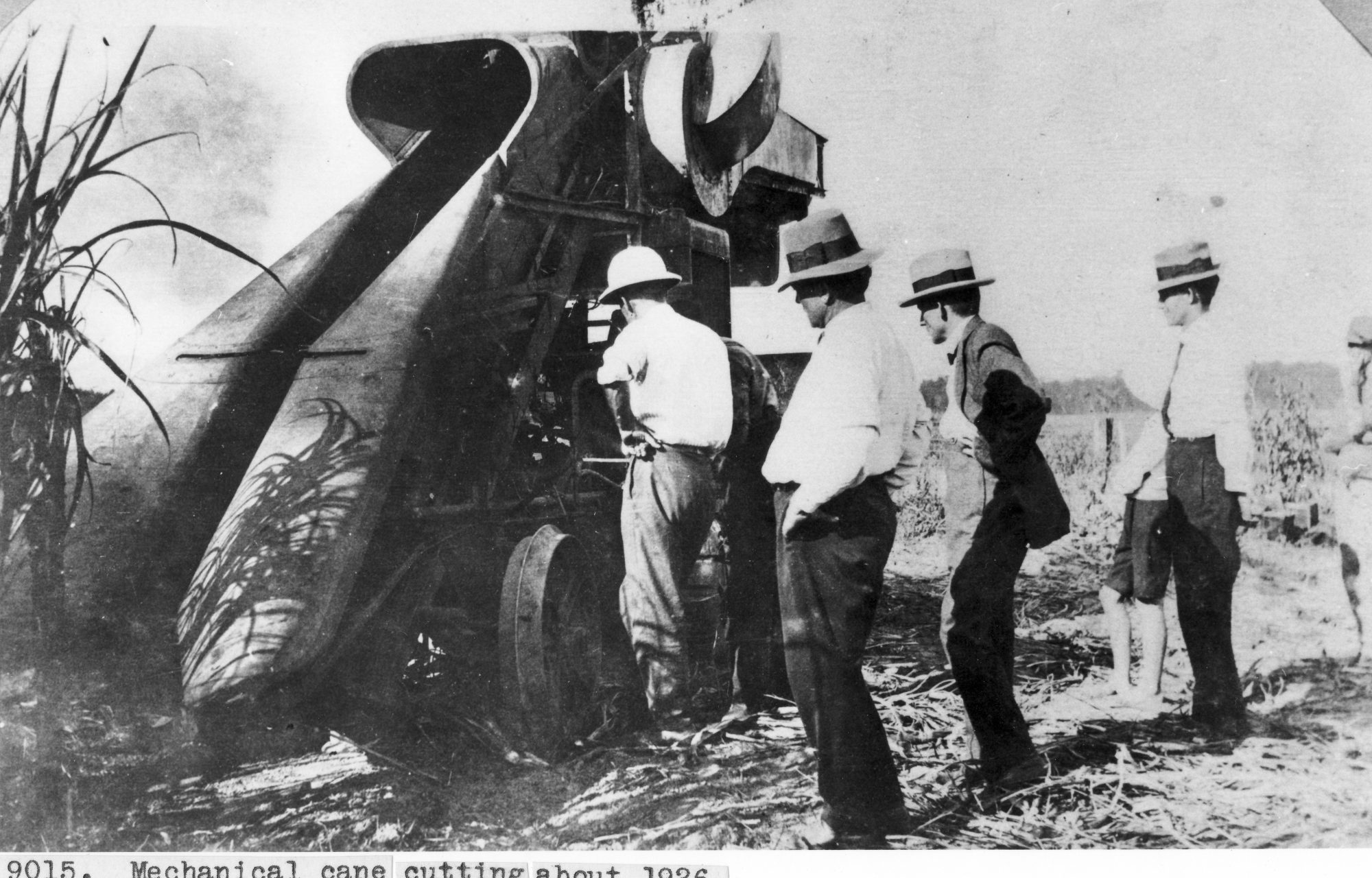

The mechanisation of the sugarcane harvest was one of the most significant transformations in the industry’s history, reshaping how farms operated and ensuring the harvest could continue as labour became scarce.

For decades, harvesting cane meant long hours of physically demanding manual labour. As production expanded, the industry became increasingly vulnerable to labour shortages caused by war, migration shifts and rising costs.

Without change, growers faced the real prospect of being unable to harvest their crop.

Wartime urgency

By 1943, the labour situation had reached crisis point. Hand cutters were scarce, costs were rising, and the future of the harvest was under threat. Mechanisation needed to occur - and quickly!

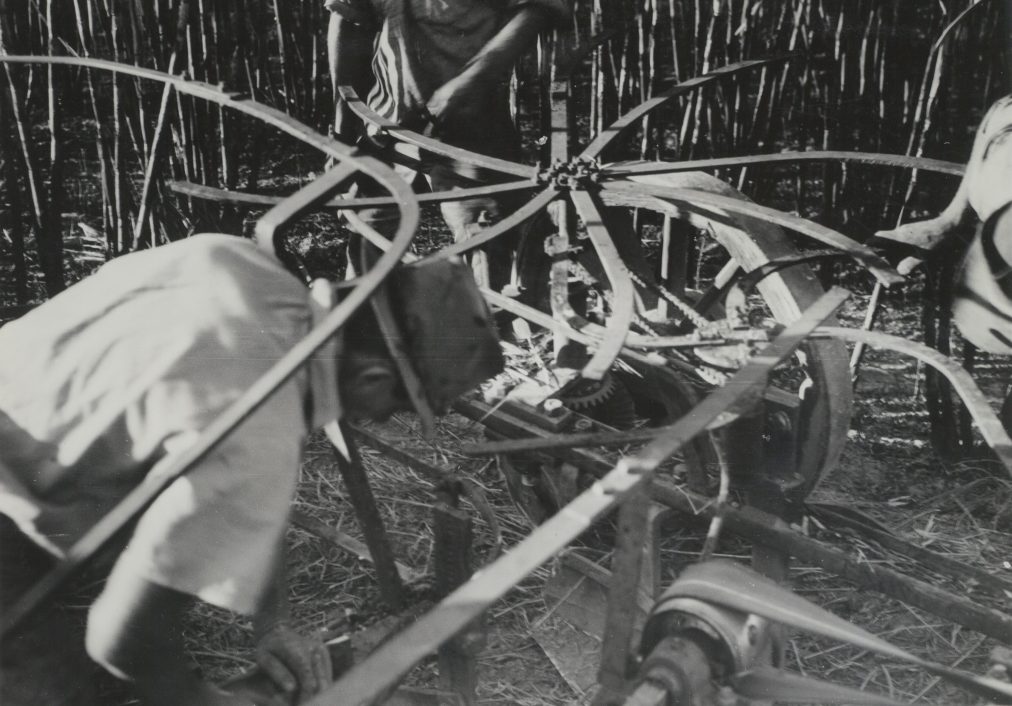

Individual inventors provided the creative spark behind early harvesting machines, but progress required more than ingenuity alone.

Many growers remembered earlier failed experiments and were understandably wary of investing in unproven technology. CANEGROWERS helped bridge that gap – providing organisation, coordination and financial encouragement when it mattered most.

Legal barriers that once prevented the use of grower funds for machinery development were removed in 1945, when changes to the CANEGROWERS Constitution empowered the organisation to actively encourage and assist the development of mechanical harvesting and loading machines.

That moment marked a turning point.

CANEGROWERS worked with growers, researchers and government to accelerate the development and adoption of mechanical harvesting, helping coordinate industry effort during a period of acute labour shortage.

What began on the margins of development quickly moved centre stage.

Investing in the future

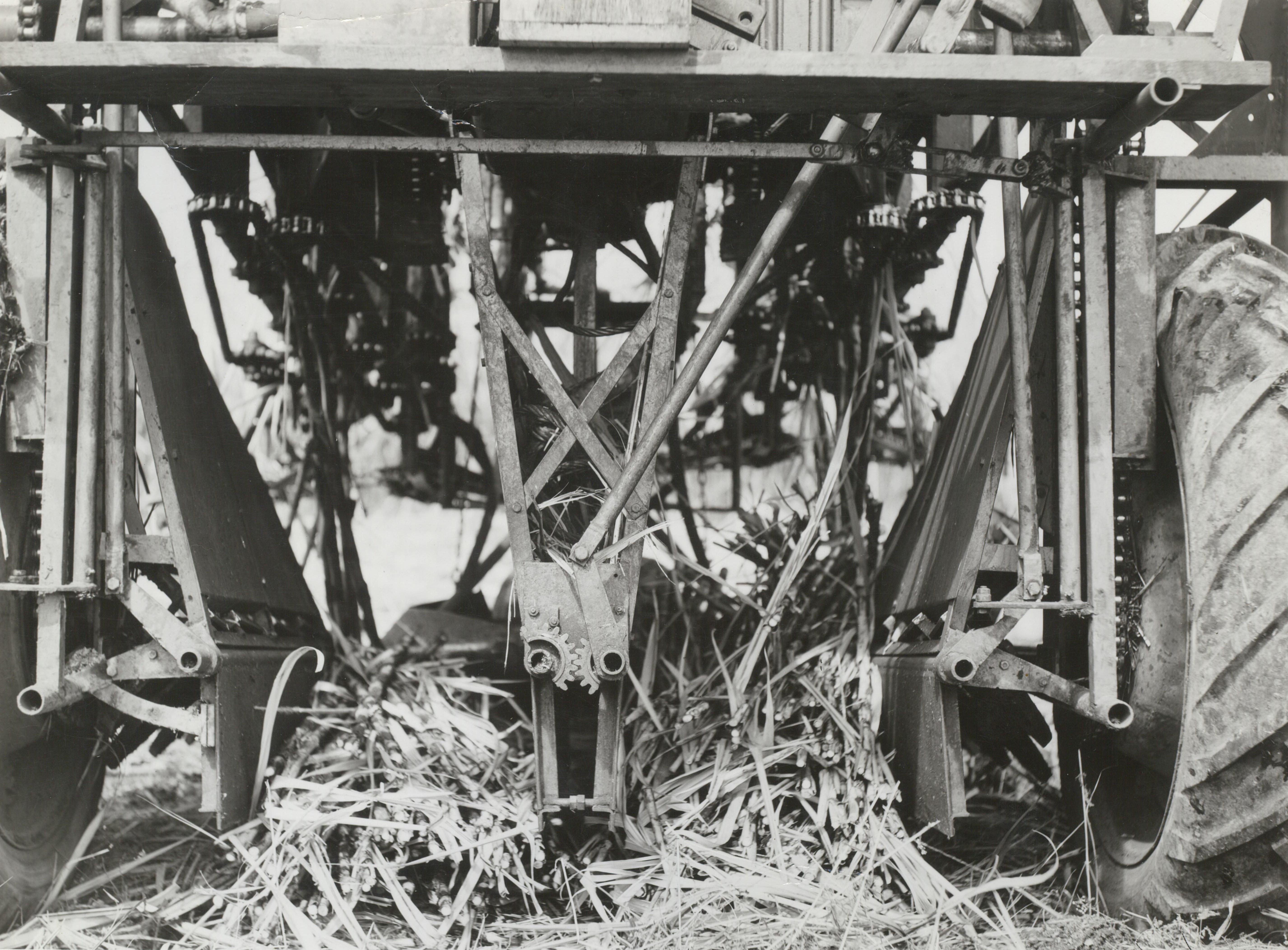

In 1944, CANEGROWERS commissioned Bundaberg grower-inventor Harold Toft to build a new harvester, supported by the organisation and overseen by its subcommittee. A Toft loader was also developed, and financial assistance was extended to other inventors working on harvesting technology.

To sustain this momentum, in 1945 the Queensland Cane Growers Council adopted a levy of one-fifth of a penny per ton of cane, creating a dedicated fund to support mechanisation research and development.

CANEGROWERS also sent a three-man fact-finding mission to the United States and Cuba, examining overseas harvesting systems and bringing those lessons back to Queensland.

From experiment to everyday practice

Machines that once seemed speculative became essential. Mechanical harvesting reduced dependence on manual labour, increased efficiency, and allowed the industry to continue growing in scale and sophistication.

Even after the Mechanical Cane Harvesting Committee was wound up following 17 successful years, CANEGROWERS continued to support innovation – including loans in the late 1960s to help develop early green cane harvesting technologies.

Mechanisation did not happen overnight. It happened because growers backed it – collectively.

A defining legacy

Mechanisation stands as one of the clearest examples of CANEGROWERS’ role beyond policy and negotiation. It shows an organisation willing to:

- confront uncomfortable realities

- invest grower funds for long-term benefit

- support inventors and early adopters

- work with government when necessary

- and drive industry-wide change

The modern harvest – efficient, mechanised and continually improving – is part of that legacy.

Adapting to survive

Ongoing refinement, automation and precision technologies have continued to improve efficiency and safety, but the foundations of modern harvesting were laid through the collective decisions of earlier generations.

Faced with labour shortages that could have crippled the industry, growers chose innovation over decline. With CANEGROWERS at the centre, they reshaped how cane is harvested in Queensland.

It is a reminder that progress in the sugar industry has never been accidental. It has been organised, argued for, funded and fought for – by growers, together.